MIT Research

What is Life Cycle Assessment?

LCA is a technique to assess the environmental aspects and potential impacts associated with a product, process, or service, by:

compiling an inventory of relevant energy and material inputs and environmental releases;

evaluating the potential environmental impacts associated with identified inputs and releases;

interpreting the results to help you make a more informed decision.

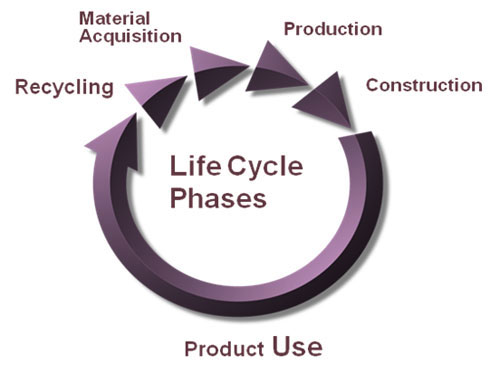

LCA attempts to assess the environmental impacts throughout the product, process or service’s full life cycle.

A life cycle consists of the following stages:

raw material acquisition

materials manufacture

production

use/reuse/maintenance

recycle/waste management

Standards associated with LCA: ISO 14000

Visit this EPA document to learn more

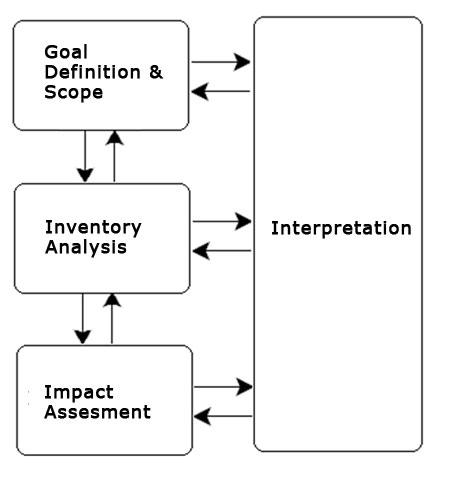

The four basic steps to the LCA are:

goal and scope definition | inventory analysis | impact assessment | interpretation

Goal and Scope Definition

In the Goal and Scope stage, the system and its boundaries, the functional unit to be used and the procedure to be followed for the study are determined.

The term “system” is the set of different processes or subsystems connected to each other that, acting at the same time, make a specific function in the life cycle of a product or process. The functional unit is the amount of material, the type of system, the service or process that is being investigated with the LCA. For example, the function unit can be one water bottle, one square meter of flooring or a full building.

The scope of the study must clearly describe the system of the studied product or process and its boundaries, the included items and the items to be evaluated, the system functions, the functional unit, the calculation unit, the impact categories, the methodology applied, and finally, the necessary assumptions and restrictions.

Inventory Analysis

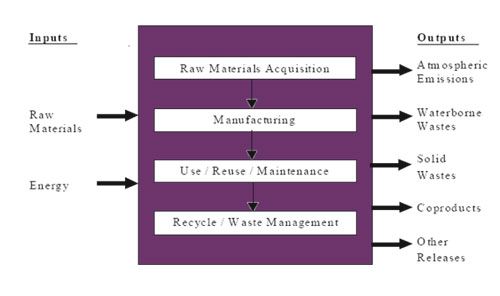

The inventory analysis is one of the more complex and time consuming stages of the LCA. In this portion of the LCA, the data is analyzed such as the materials entering the system: raw materials, water, agents, fuels and other natural inputs. The materials exiting the system are also analyzed: products, air emissions, liquid effluents, by-products and wastes. This data is recorded and quantified. These data constitute the inputs to the next stage of Impact Assessment.

Data collection is the basis of the Inventory Analysis. It is a complicated and time consuming process. Potential sources of data can be research, site visits, direct contact with experts, commercially available LCA software packages and other non-site specific inventory data.

Impact Assessment

In the Impact assessment, the effects of the environmental burdens identified in the Inventory Analysis stage are characterized and assessed. This analysis helps to estimate the possible environmental impacts which are related to the recorded inputs and outputs. The selection of appropriate impact categories on the basis of the existing inventory data, the general knowledge about cause-effect relationships and the assignment of the inventory data into the different impact categories, constitute the first step of the Impact Assessment stage and it is called Classification.

The most common impact categories are, however, there is no common methodology for determining which categories to include in a LCA:

Resources consumption (oil, gas, coal, selected minerals)

Carcinogenesis

Ozone layer depletion

Climate change

Human toxicity (formaldehyde, toluene, metals to air)

Eco-toxicity (dioxins, PAH, PCB, metals, etc)

Acidification (SO2, NOX, NH3)

Water and terrestrial eutrophication (P (to water), N (to water), NOX, NH3)

Photochemical oxidants formation

Land use

Noises and scents

Effects on human health in the work place

Waste generation

Conservation of natural resources and diversity of species.

In the last step of the Impact Assessment stage, the valuation, the contribution from the different specific impact categories are weighted so that they can be compared among themselves.

Interpretation

In this final step, interpretation, the results are analyzed and recommendations are provided. The final output of the analysis should be a set of improvement scenarios, which will help reduce the environmental burdens brought on by a product or process.